The Real Fact: High-quality SRF Alternative Fuel Should Look Like This!

In 2023, with the release of policies to reduce carbon emissions and energy consumption, and the price of coal continues to remain high, many cement companies have begun to lay out the "RDF/SRF alternative fuel" market.

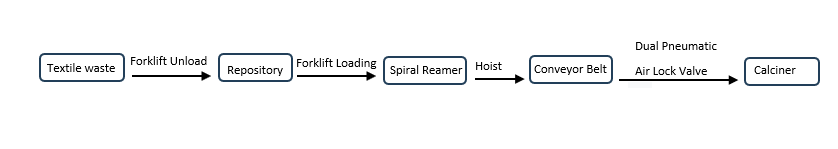

One cement company in Guangdong province has set up a simple waste textile SRF alternative fuel transportation and feeding system (as shown in the picture)

The waste SRF is fed through the frequency conversion speed control of the spiral reamer. After being lifted to the preheater by the elevator, it is fed into the decomposition furnace through the conveyor belt and the pneumatic air lock valve.

The experimental conclusion shows:

The dry basis calorific value of SRF alternative fuel prepared from waste spinning is about 5, 000 × 4.18 kJ/kg. It can effectively reduce standard coal consumption.

Choose high-quality SRF alternative fuel with lower CL content after screening equipment. Pay attention to the changes in the content of MgO, SO3, and Cl- when using it.

Small bulk density waste spinning SRF alternative fuel requires a larger-sized conveying and feeding system.

The size of the SRF alternative fuel is recommended to be 50~200 mm to reduce feeding interruptions.

With more than 100 t/d SRF usage, the feeding points should be arranged at multiple points and arranged above the tertiary air to ensure the dispersion and combustion effects in the decomposition furnace.

Harden integrates Germany's cutting-edge solid waste treatment technology concepts and launches an integrated and modular comprehensive treatment system that meets the characteristics of various general industrial solid wastes.

Through refined processes such as "double-stage crushing + magnetic separation + air separation + sorting + dust removal", the SRF alternative fuel obtained has been greatly improved in terms of discharge size, iron removal (cl) rate, and impurity removal rate. The heat loss coefficient is lower, and the average combustion heat value of alternative fuels reaches more than 5,000 calories.