How to process ragger wires produced in the paper industry?

What is Pulper Rope (Ragger Wire) ?

Ragger wires, also known as pulper tails, and pulper ropes are waste products from the paper industry. They are created when waste paper is recycled in the pulper and absorbs impurities such as plastics, small metal parts, foils, and non-soluble paper.

Total of 30-35 % of the wet ragger wire coming from the pulping process consists of steel wires. Rest of the material when dried is ready-to-burn RDF after shredding and metal separation. But what is the best way of recycling these pulper ropes?

Value of the Ragger Wire

Processing them into alternative fuels has been proved to be the most effective way of recycling pulper ropes and paper production rejects. This yields two marketable materials: metal as well as high-calorific alternative fuels for energy production.

• Recover valuable steel – nearly 45% content.

• Generate revenue instead of waste.

• Residual waste becomes alternative fuel.

• Save landfill space and reduce storage and transportation/disposal costs.

Features of Harden's One-stop Ragger Wire Recycling System

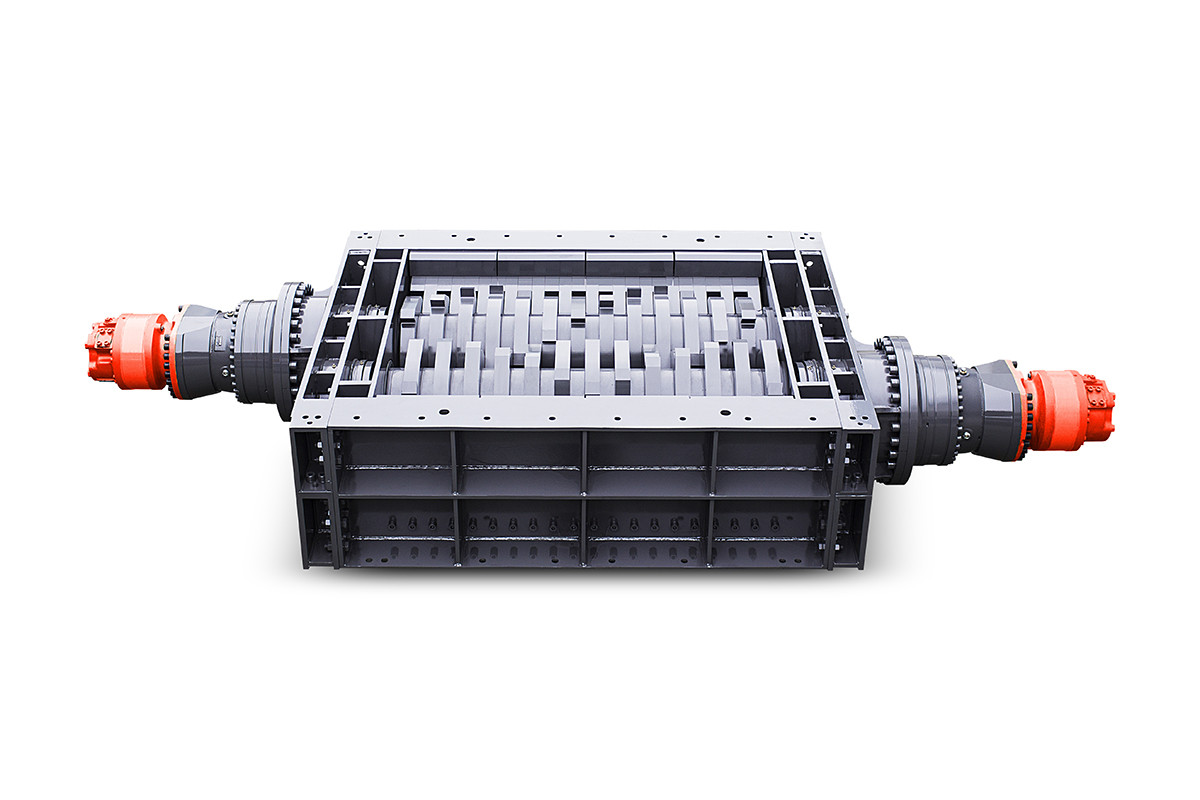

Harden has developed a one-stop ragger wire waste processing system, including the ragger wire shredder, hammer mill, and ferrous separator. This kind of system is prevalent in the market, harden one-stop ragger wire processing has received thousands of successful cases since released.

Chain Conveyor+ Harden Shredder+ Hammer Mill+ Ferrous Separator

•Conveyor transport for labour reducing

•Low noise, dust, and knives wear

•Self-discharging ferrous separators

•Automatic central controller for safe and easy operation

•Horizontal packing machine saves transport and loading cost

Recommended Harden's Ragger Wire Shredder

|

Motor

|

TD912

|

TDH1216

|

|

Drive

|

electrical system

|

hydraulic system

|

|

Motor power (KW)

|

75+75

|

200

|

|

Cutting chamber (mm)

|

900*1220

|

1200*1600

|

Machine dimension (mm) | 4500*2200*2800 | 3408*2900*3600 |

Machine weight (kg) | 10000 | 15000 |

Video

Title