Harden Industrial Hazardous Waste Processing Technology

Generally solid waste includes municipal waste, industrial solid waste, and hazardous waste, and the industrial hazardous wastes in this article refer to hazardous products which are produced or discharged. The production or processing of industrial plants and mining enterprises. It is classified on the "National Hazardous Waste List" or recognized as hazardous solid waste. The most common hazardous solid waste are paint buckets, paint residue, oilcloth, waste oil, and oil sludge that is used or discharged during the production.

Three Processing Technology of Industrial Hazardous Waste Disposal

For environmental health, industrial hazardous wastes must be collected, transported, disposed of, and managed in accordance with the relevant national requirements. Currently, there are three main industrial hazardous waste disposal ways, industrial hazardous waste incineration process, industrial hazardous waste physical and chemical treatment process, industrial hazardous waste incineration & landfill treatment process.

Disposal Difficulties During the Industrial Hazardous Waste Processing

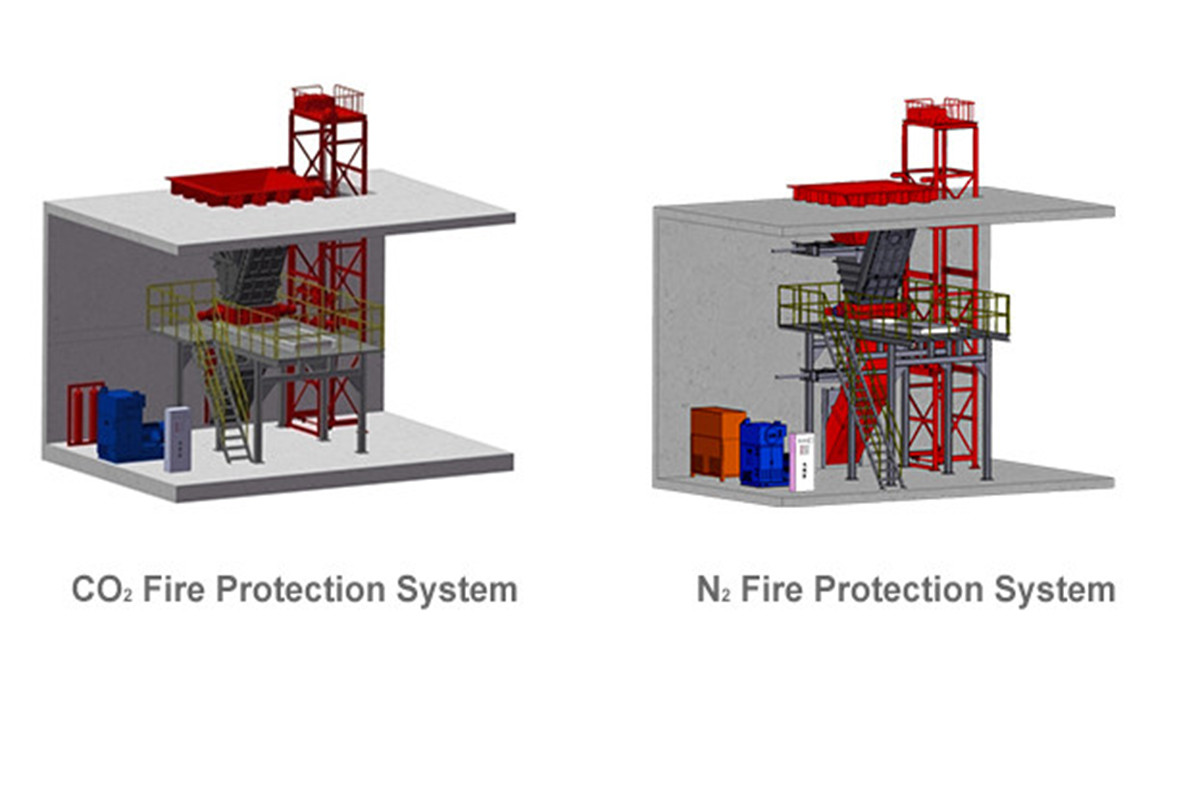

In the case of industrial hazardous waste with low ignition and explosive gases, there is a lot of heat generation,severe collision, strong agitation, and other unstable factors in the process of shredding, which can easily lead to explosion or fire, so the industrial hazardous waste disposal system must be equipped with multiple safety protection.

Harden's Industrial Hazardous Waste ProcessingTechnology and SMP System

Harden company carries thousands of successful cases of industrial hazardous waste disposal. Superstar to dispose of industrial hazardous waste disposal is the model TDH912, which comes with a hydraulic driven system. The most representative industrial hazardous waste processing system is SMP system, it contains the main three procedures for industrial hazardous waste disposal--Shredding, Mixing, and Pumping.

Shredding: Hazardous waste will be shredded by Harden's powerful industrial hazardous waste shredder

Mixing: Mixing conditioner makes the industrial hazardous waste suitable for pumping

Pumping: A robust pump feeds the kiln with fully sealed tubes

Features of Harden's Industrial Hazardous Processing System

Ø Lifter+Shredder+FireControl System

Ø Lifter+Shredder+FireControl System+Mixer+Pump

l Driven by a world-class hydraulic system

l Quality hydraulic components with 35 Mpa of maximum pressure

l Automatic overload protection

l Knives are made of high-strength alloy, no worry of metal crushing

l Knives can be repaired by welding to reduce the maintenance cost

l Double seals, dust-proof maze, and material baffle for core part protection

l Automatic fire extinguishing system

l Maintenance mode for easy, safe operation

l Forced feeding by the hydraulic press

l Siemens and Schneider electric components ensure high stability

Recommended Harden's Industrial Hazardous Waste Shredder TDH912

Parameters

|

Model

|

TDH912

|

|

Motor power (KW)

|

75*2

|

|

Cutting chamber (mm)

|

900*1200

|

|

Cutter size (mm)

|

Φ400*50

|

Quantity of blades (pcs) | 20/40 |

Voltage, frequency (V/HZ) | 380/50 |

Machine dimension (mm) | 5100*2800*3200 |

Machine weight (kg) | 2900 |

Throughput (tons/h) | 10-20 |

Title