The Resource Utilization Rate of Bulky Waste Processing System Reaches 100%

Since the

implementation of waste classification in Beijing, great attention has been

paid to the treatment of bulky waste, and it is required that each street must

set up at least one temporary storage place for bulky waste. The streets with

conditions can also be equipped with bulky waste treatment stations, or directly

handles the waste on-site. Each district should set up at least one centralized

dismantling and disposal center.

E20 environmental

Platform group visited the first bulky waste resource treatment center in Daxing

district, Beijing. Zhang Zhenguo, general manager of customer, and Wu Binbin,

deputy sales director of Harden sales Department, were in charge of the

reception, and introduced the technical process and operation of the center in

detail.

Zhang and Wu introduced

that the project, located in Huangcun Town, Daxing District, Beijing, covered

an area of about 70,000㎡, with a total construction area of 16,000㎡. The daily capacity is about 160 tons, and

the system can realize 100% resource utilization of bulky waste, which has been

officially in operation.

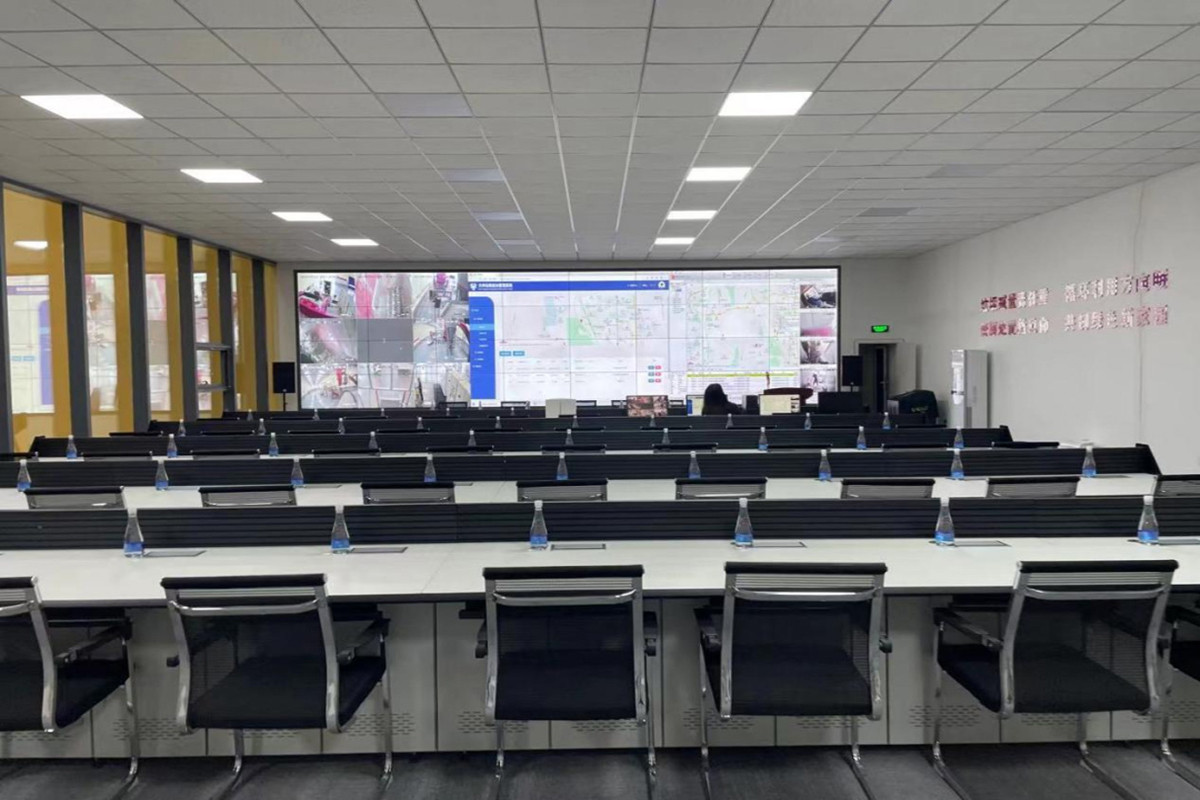

With the help of

the technological means of Internet of things, the bulky waste

treatment project has established its own recycling system, combined with the

new core technology scheme of bulky waste resource disposal, so that the

resource utilization rate of bulky waste can reach 100%, and the bulky waste

can be truly turned into treasure.

Residents can

download APP to make an appointment for the collection and transportation of

bulk waste. All operations are online, which is convenient and quick. Based on

technologies such as Internet of Things, cloud computing,

big data, AI, GPS positioning and visualization

equipment, the data center provides information management solutions

for the whole life cycle of bulky waste collection, transportation, management

and disposal, realizes real-time, controllable and efficient operations of bulky

waste management and disposal.

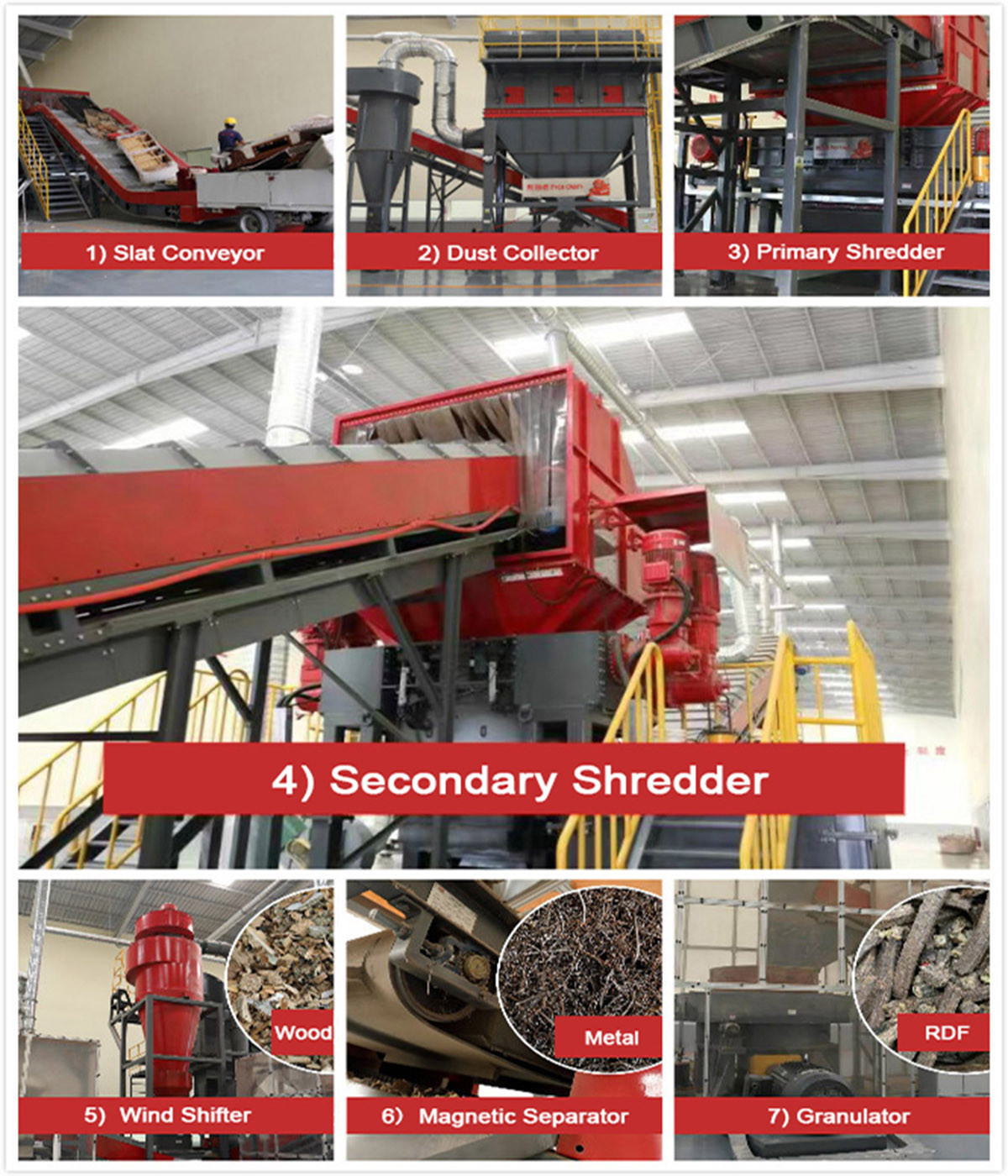

The Process of Bulky Waste Processing System Provided by Harden

1)

The

bulky waste is fed into the primary shredder by slat conveyor.

2)

The

entire system is free of dust.

3)

The

discharge of bulky waste is about 300mm after primary shredder.

4)

The

secondary shredder improves shredding efficiency and reduces the discharge size.

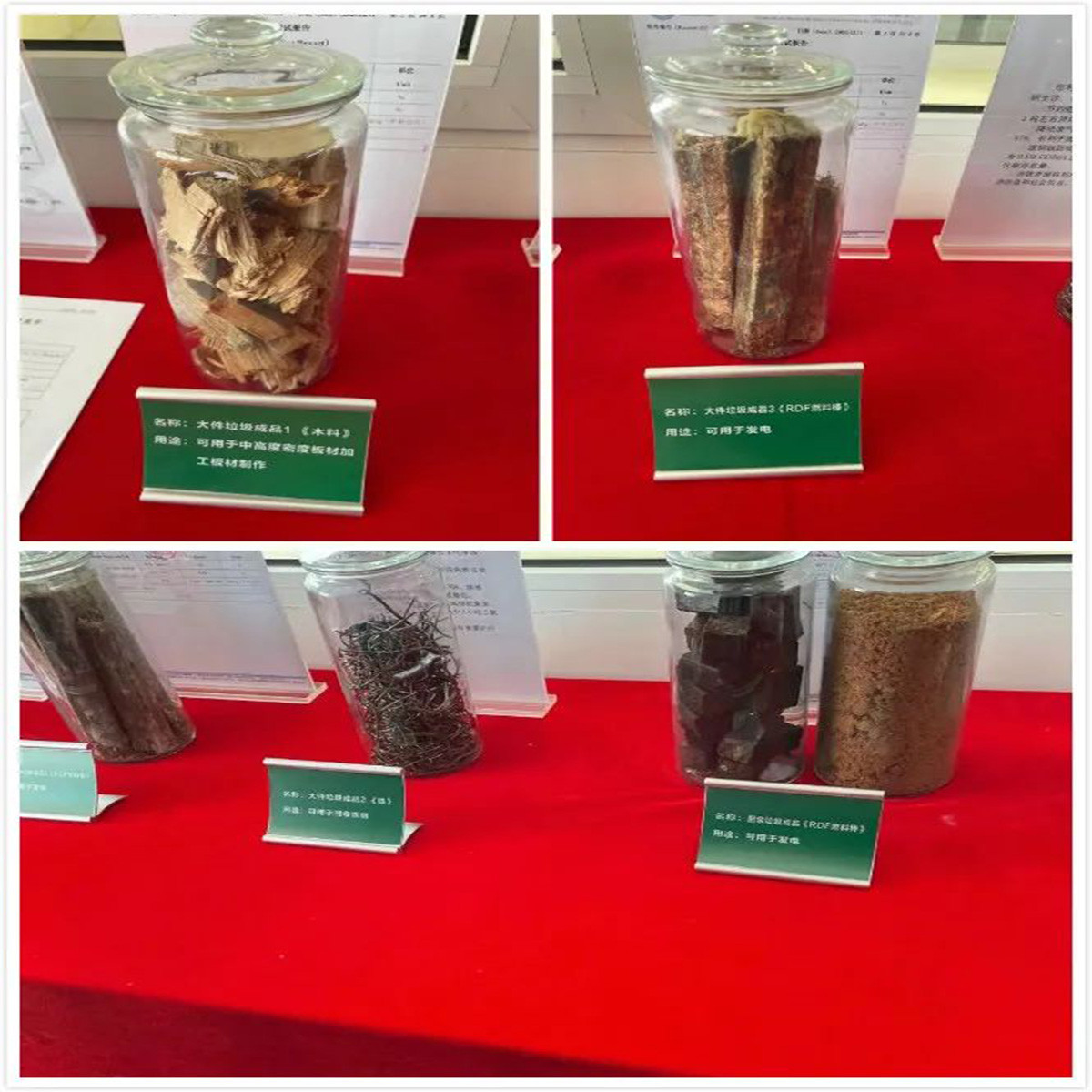

5) Wind

shifter achieves weight separation, the finished products can be used to make

plates or incineration power generation.

6) Steel

wire can be sorted by magnetic separator.

7) The

granulator produces a high calorific value RDF that can be used as an

alternative fuel.

Harden is committed to providing customers

with solid waste shredders and overall solid waste solutions. Relying on strong

R&D strength and advanced solid waste shredding technology concept, Harden provides

the global customers with convenient operation and stable performance of single

shaft shredder, double shaft shredder, four shaft shredder, primary shredder

and entire solutions based on hazardous waste, domestic waste, bulky waste,

kitchen waste, waste rubber tires, paper mill waste, industrial solid waste,

medical waste, organic waste, etc.

In the future, Harden will continue to

focus on technological innovation and product upgrading to provide stronger

power for the development of the industry.

If you need any help with waste management, please

contact us and we are willing to offer you the best service.